Your Strategic Partner for Precision Scientific Glass

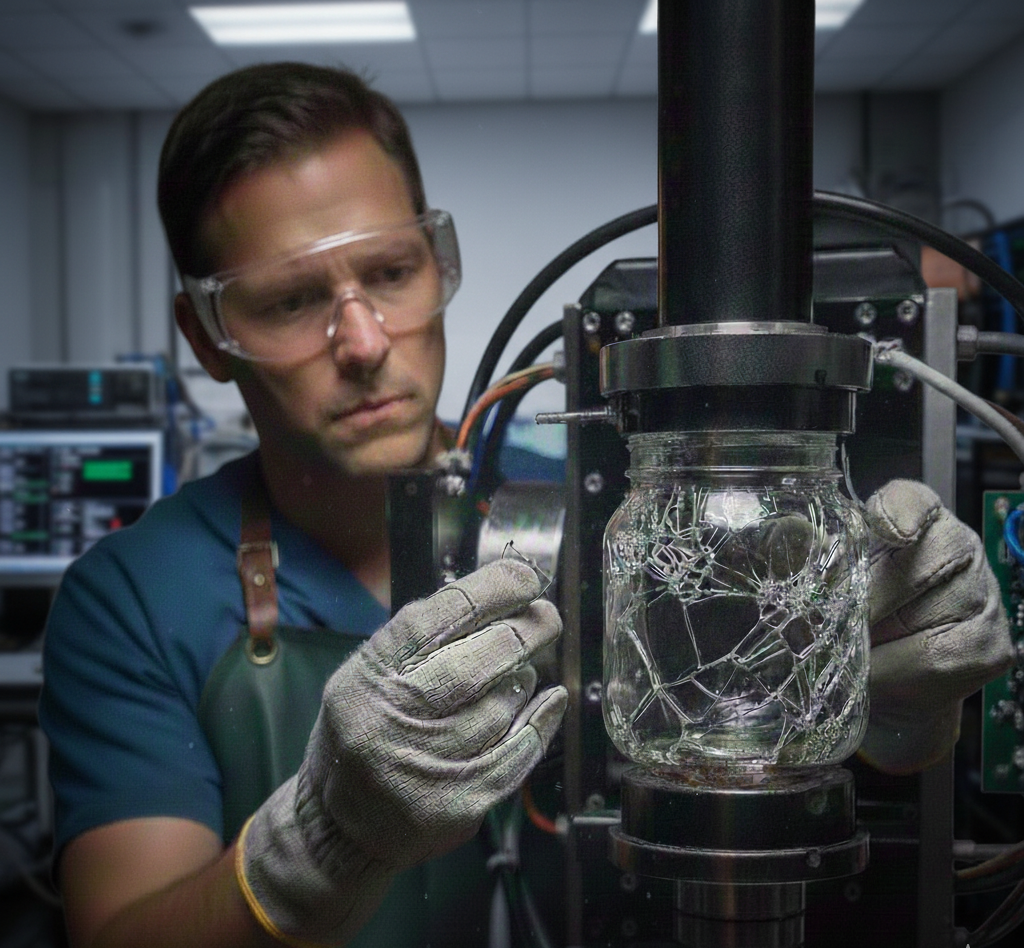

Precision Glass Components That Keep Your Instruments Running Flawlessly

When analytical accuracy matters, your glassware must be engineered to the same exacting standards as your instruments.

Whether you're an OEM building instruments that researchers depend on, or a laboratory conducting measurements that can't afford to be wrong, we're the scientific glassblowing partner who understands what's at stake. For 45 years, we've delivered custom glass components with the precision and reliability that keeps your production schedule on track and your customers confident.

45+ Years in Precision Scientific Glassblowing

Trusted by Leading OEMs & Research Institutions

Master Glassblowers with Decades of Specialized Experience

Made in USA

The High Cost of "Almost Perfect" Glass

Here's What's Really At Stake When Your Glass Components Aren't Flawless

Your critical glass components are the foundation of your results. When they fail, the consequences cascade through your entire operation:

Operational Delays

Instruments go out of calibration and production halts

Data Integrity Risks

Environmental and analytical tests become unreliable

Wasted Resources

Lamps fail prematurely and research stalls for months

The real challenge isn't just sourcing glass, it's finding a manufacturing partner who grasps the technical demands of your work and delivers components that perform to spec, on time, every time.

For over four decades, that's exactly what we've done. And we've built our reputation on understanding that your operation can only run as flawlessly as the components we build for you.

Industries & Applications Where Precision Isn't Optional

From analytical instrumentation to defense applications, our glass components serve the most demanding sectors in science and industry. Each faces unique challenges that demand more than off-the-shelf solutions.

OEM Analytical Instrument Manufacturers

Your Challenge:

Supplier failures derail production schedules

Our Solution:

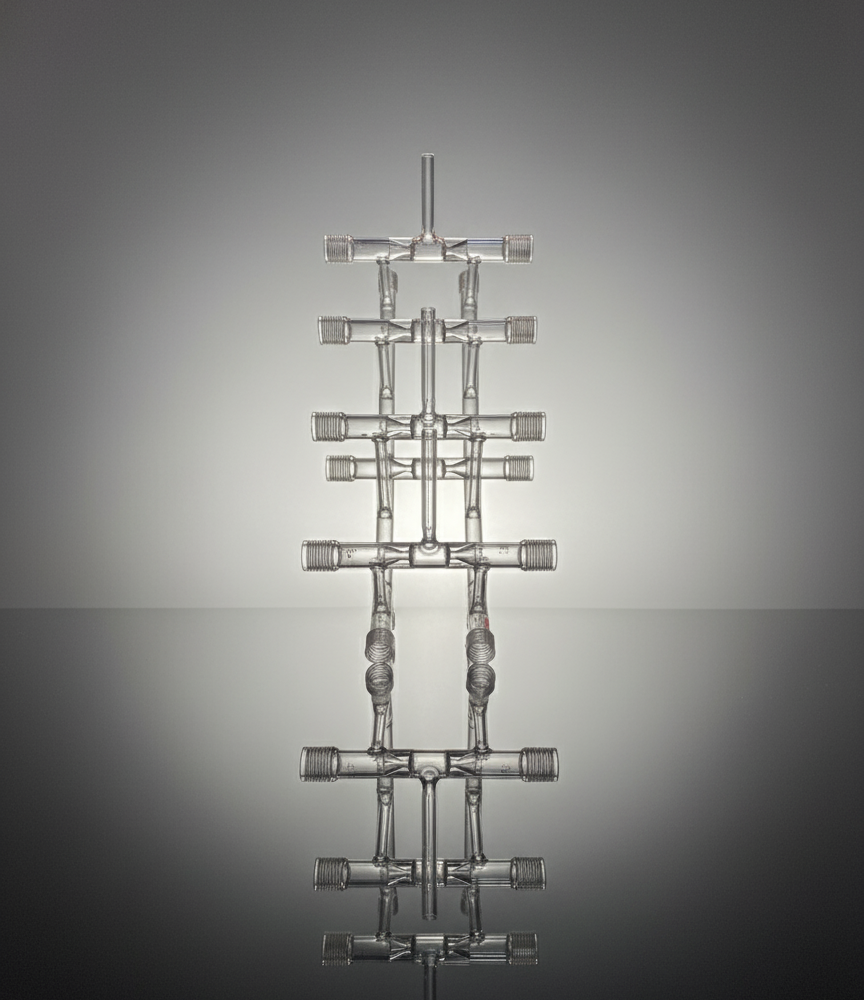

Flow cells, gas cells, and custom components engineered for seamless integration

Environmental Testing Laboratories

Your Challenge:

Regulatory compliance requires certified glassware with complete traceability

Our Solution:

Condensers, Soxhlet extractors, vacuum systems, and soil funnels built to spec

Analytical Lamp Manufacturers

Your Challenge:

Glass must survive millions of ignitions with zero drift or leaks

Our Solution:

PID lamps, hollow cathode lamps, and precision components for extreme reliability

Department of Defense & Specialized Applications

Your Challenge:

Mission-critical components with zero margin for failure

Our Solution:

X-ray tube components and specialized glass for advanced systems

Pharmaceutical Research Facilities

Your Challenge:

Compliance and validation aren't negotiable

Our Solution:

Custom laboratory glass manufactured to pharmaceutical-grade standards

Academic & Quality Control Laboratories

Your Challenge:

Pushing boundaries while maintaining measurement integrity

Our Solution:

Custom fabrications where a single measurement error can cost millions

45 Years of Getting It Right, And We're Still Obsessed

Why OEMs and Laboratories Trust Us With Their Most Critical Glass Components

At Vitro Technology, Ltd., scientific glassblowing isn't just what we do, it's all we do. Here's what that means for your operation:

1.Uncompromising Quality Through Deep Expertise

Our Master glassblowers bring decades of specialized experience to every component. This isn't a side business or a general fabrication shop, we've built our entire reputation on precision craftsmanship and exacting standards. We've earned the trust of OEMs and laboratories worldwide by delivering scientific glass that meets exact specifications, right the first time, every time.

2.We Speak Your Language

Our Master glassblowers and engineers don't just know glass, they understand the critical role it plays in your analytical instrumentation. We bridge the gap between design and fabrication, translating your technical requirements into precision glass components that integrate seamlessly into your systems. Whether you're developing new equipment or maintaining existing production lines, we work as an extension of your team.

3.Your Deadlines Become Our Deadlines

We give you transparent timelines based on real capacity, not optimistic guesses. When we commit to a delivery date, you can schedule your production around it with confidence. We understand that delays in glass components mean delays in your entire operation, so we treat your deadlines with the same urgency we'd expect for our own.

The result? Glass components that perform flawlessly, delivered when you need them, backed by a team that understands the technical stakes of your work.

From Concept to Delivery: Your Project in Expert Hands

A Streamlined Process Built on 45 Years of Precision Manufacturing

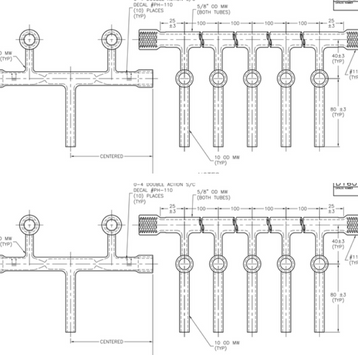

Technical Consultation

Share your specifications, drawings, or even just a concept. Our engineers and Master glassblowers review your requirements and provide technical guidance on materials, tolerances, and manufacturability.

Precision Fabrication

Using advanced glassblowing techniques and decades of hands-on expertise, we fabricate your components to exact specifications with measurable dimensional accuracy.

Quality Verification

Every component undergoes rigorous inspection to ensure it meets your specifications. For certified applications, we provide complete traceability documentation.

On-Time Delivery

Your components arrive when promised, ready for integration into your instruments or immediate use in your laboratory.

A Clear Path Forward

A simple three-step process that removes complexity and delivers results

Design & Consultation

Collaborative design with your engineering team. Expert insight for manufacturability, feedback and optimization for functionality.

Prototype & Validation

Meticulous crafting of first-article prototypes. Rigorous testing for compliance with specifications. Iterative refinement for form and function.

Production & Delivery

Seamless transition to scaled production. Consistent quality with each delivery. On-time delivery aligned with your production schedule.

Ready to Work With a Partner Who Gets It Right?

For 45 years, we've been the precision glassblowing partner that OEMs and laboratories depend on when failure isn't an option. Whether you're launching a new instrument line, scaling production, or need a critical component fabricated to exact specifications, we're ready to prove why the most demanding organizations in science and industry choose Vitro Technology, Ltd.